DN Solutions DVF 5000 — 5-Axis Machining Center

Complex parts, multi-face machining, high precision

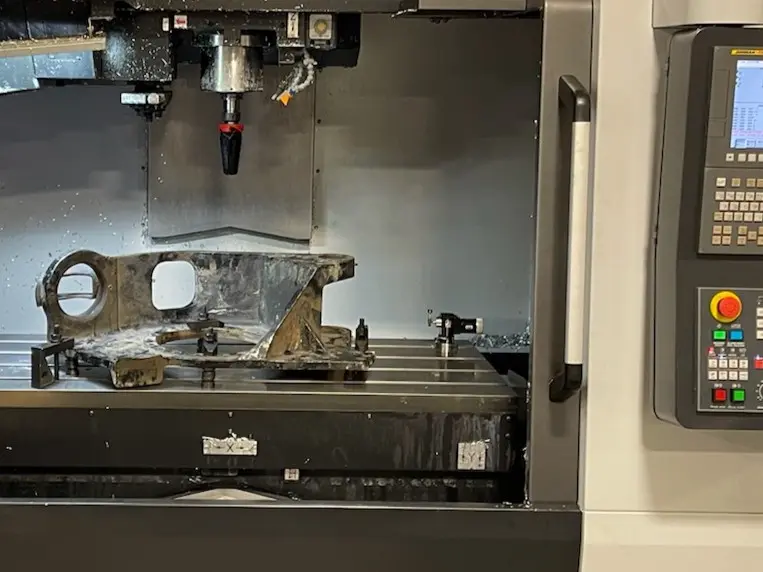

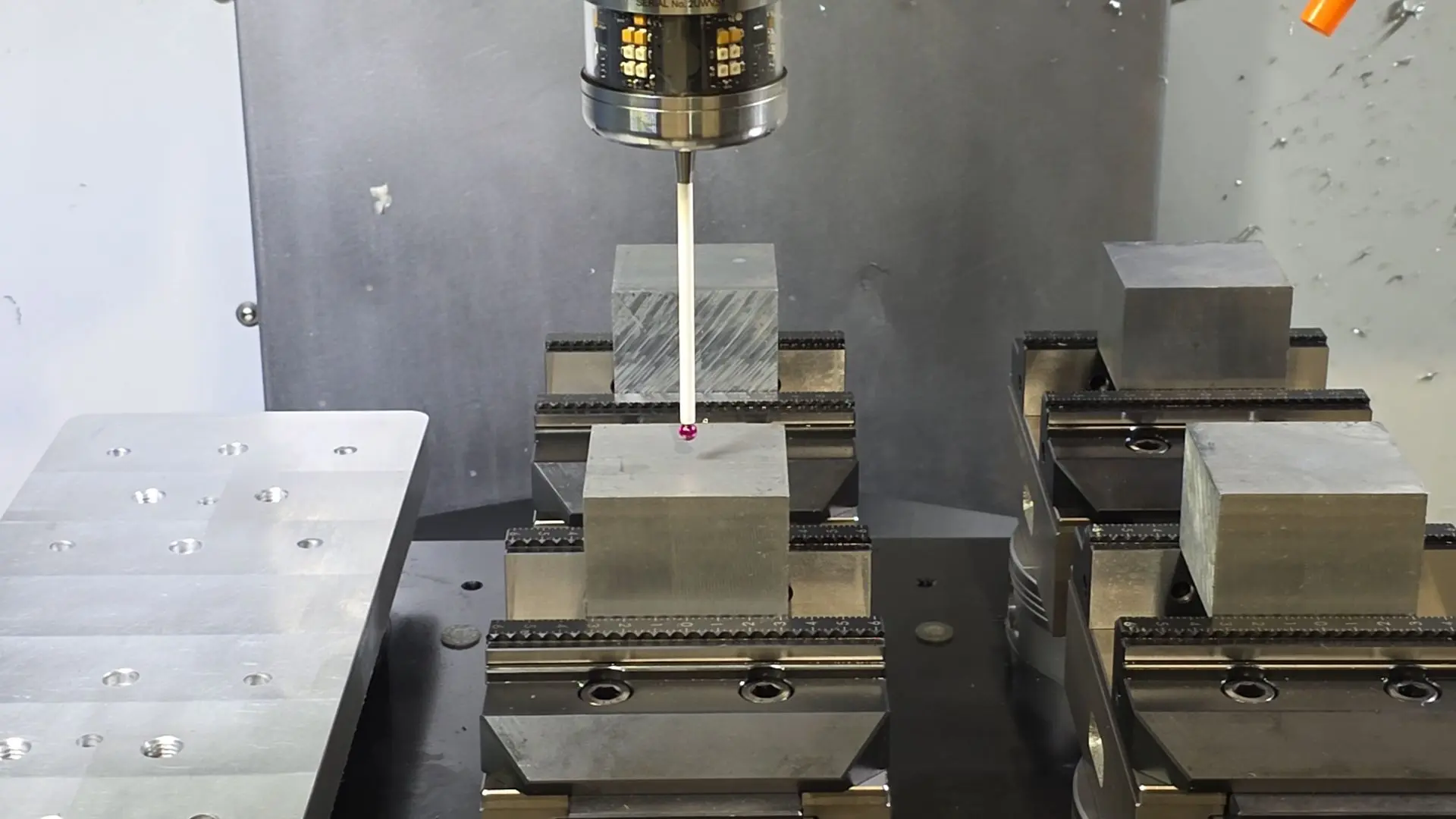

The DVF 5000 is the core of our advanced machining capability. This 5-axis machining center allows us to complete highly complex parts in a single setup, reducing the need for repositioning and dramatically improving accuracy. Its rotary table and full simultaneous motion enable machining of deep pockets, sculpted surfaces, compound angles, and multi-sided features that would otherwise require multiple fixtures.

Typical Part Capacity:

- Best suited for parts up to ~20"–24" (500–600 mm) in diameter or envelope

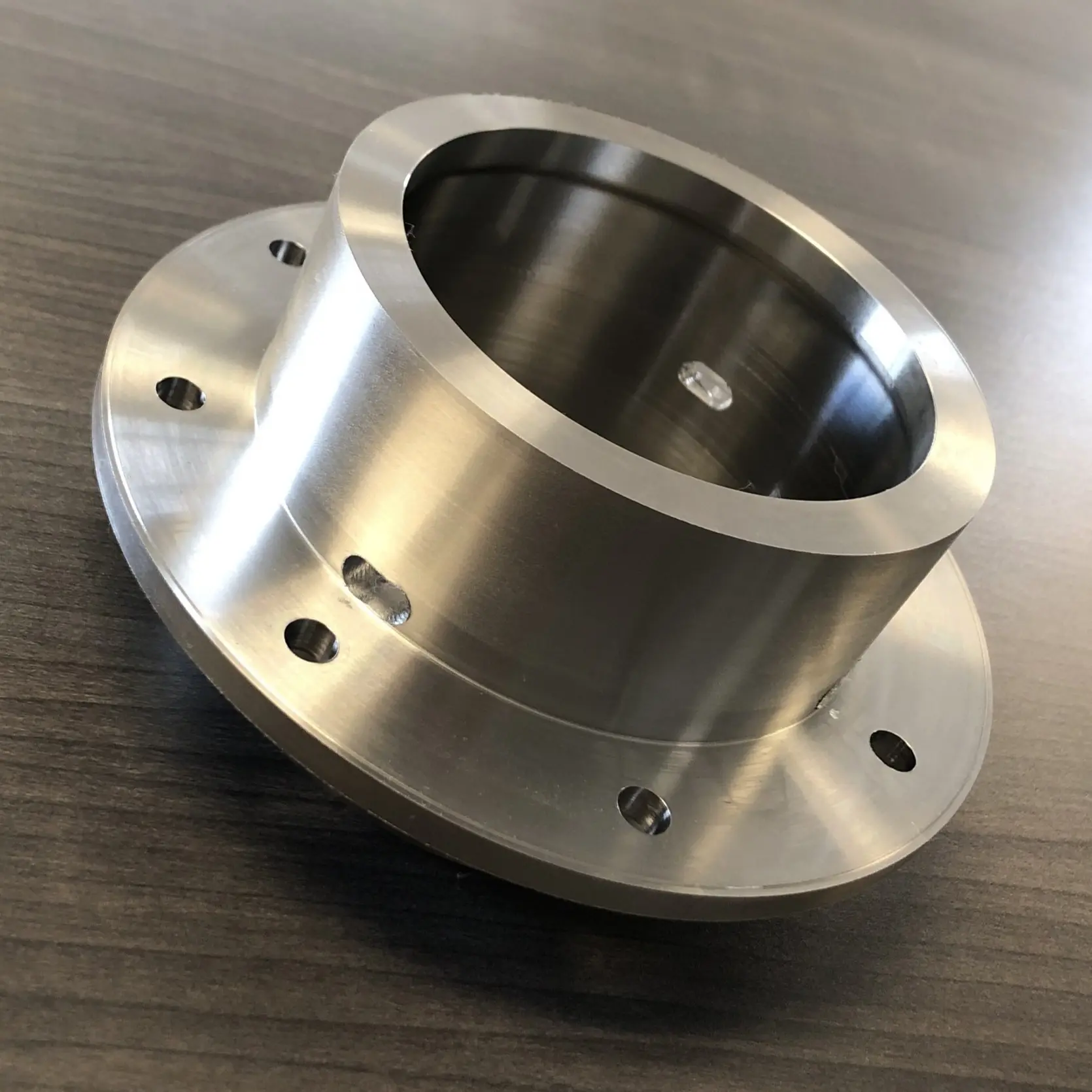

- Excellent for organic shapes, aerospace-style surfaces, manifolds, impellers, brackets, and precision housings

Why It Matters:

- Multi-face machining in a single setup

- Higher accuracy due to fewer work holding changes

- Ideal for prototypes and production where complexity matters

- Exceptional surface finish and tight-tolerance performance

- Automated probing ensures repeatability across batches

This machine unlocks design possibilities that traditional 3-axis machines simply cannot reach.