Our Services

SFC Tec Inc. provides modern CNC machining, advanced metal fabrication, laser welding, CAD design, and prototyping services for customers who need fast turnaround and reliable quality. Whether you’re ordering a simple CNC-machined part through our instant quote brand, Rapid CNC Parts.com, or working with us on a complex, multi-step project, we’re built to support you from concept to finished part.

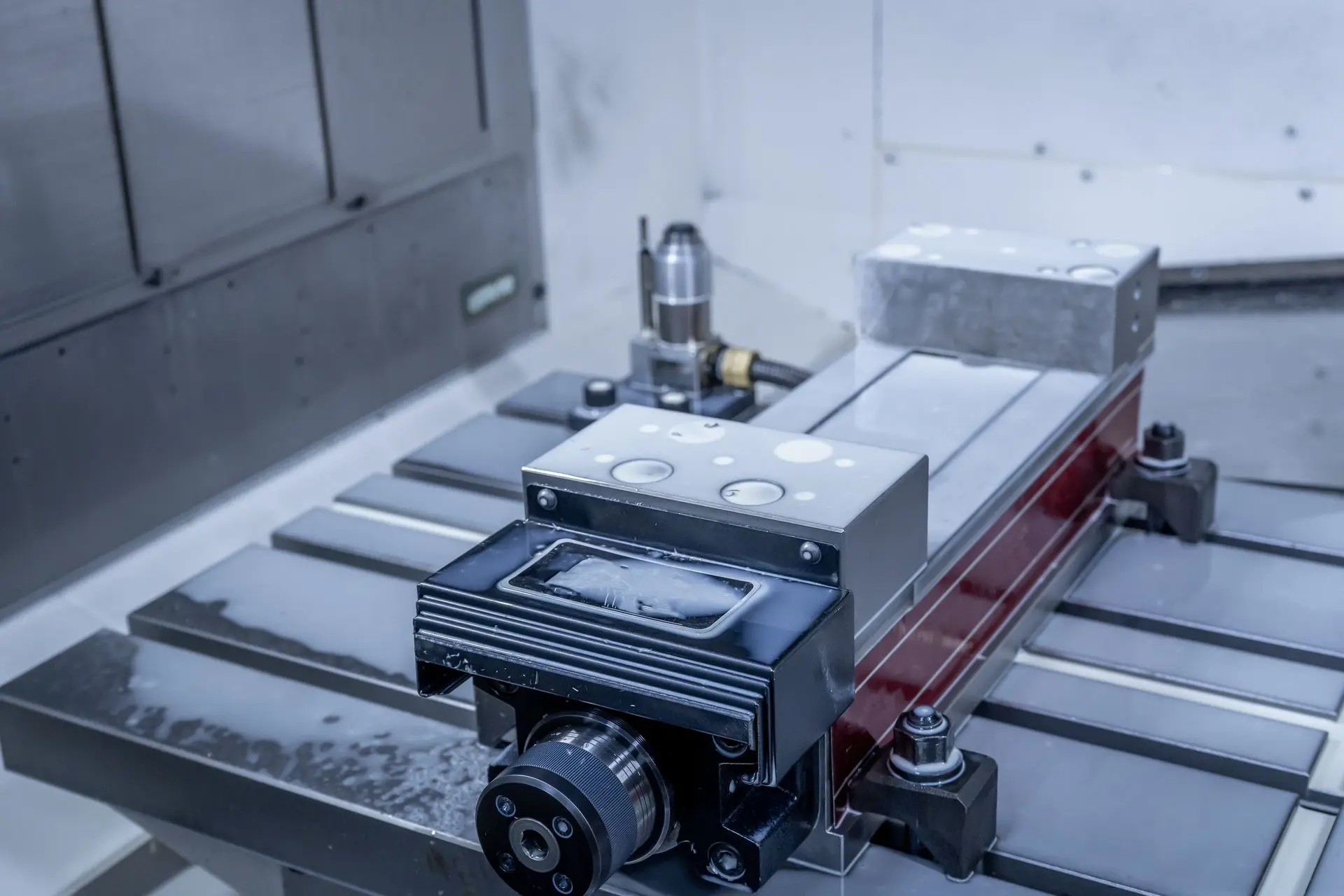

CNC Milling & Turning

Our advanced 3-axis and 5-axis vertical machining centers, combined with precision mill-turn capabilities in our CNC lathe, allow us to produce high-precision parts for both prototype and production work.

We regularly machine components for:

- Motors, pumps, engines, and gear systems

- Manifolds, brackets, mounts, and fixtures

- Custom dies, housings, and enclosures

- Complex aluminum, steel, and stainless parts

With automation, standardized tooling, and modern CAM workflows, we can efficiently run both high-volume production and one-off or small-batch prototypes.

For simple aluminum parts and standard geometries, our instant-quote brand Rapid CNC Parts.com offers a fast way to upload your CAD file, receive instant pricing, and place orders online. For complex parts, specialty materials, and advanced machining, SFC Tec Inc. manages the project directly.

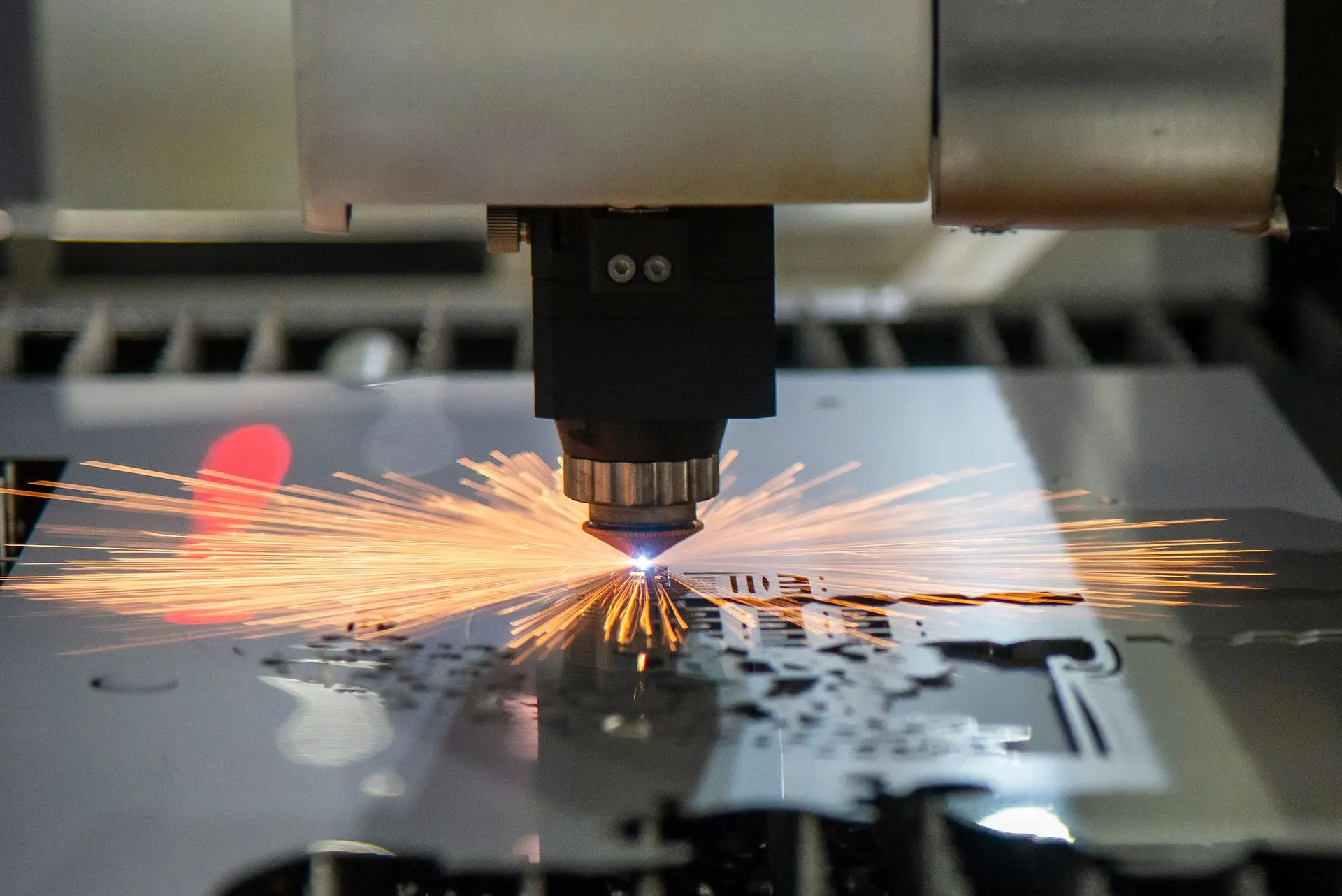

Laser Cutting Services

SFC Tec operates a 12 kW Accurl fiber laser, delivering fast, precise cutting for sheet and plate with excellent edge quality and repeatability. By keeping laser cutting fully in-house, we maintain tighter control over quality, lead time, and downstream fabrication processes.

Our Fiber Laser Cutting Capabilities

- Cutting Format: Up to 5 ft × 10 ft sheets

- Materials: Carbon steel, stainless steel, aluminum

- Maximum Thickness (Published Specs):

- Carbon steel: up to 1.50 in

- Stainless steel: up to 1.00 in

- Aluminum: up to 0.75 in

Ideal for complex profiles, tight tolerances, and parts requiring minimal secondary finishing, our fiber laser cutting integrates seamlessly with forming, welding, and CNC machining.

Plate & Material Preparation

To support efficient fabrication and machining workflows, we also provide accurate in-house material preparation.

Horizontal Bandsaw Cutting

- Precision cutting for bar stock, flat bar, angle iron, tubing, and structural shapes

- Consistent, repeatable cuts for prototypes and production work

- Optimized material prep prior to machining, welding, or assembly

By combining high-power fiber laser cutting with efficient material preparation, SFC Tec delivers a streamlined cutting solution that supports everything from one-off parts to production assemblies — all under one roof.

Traditional Welding & Laser Welding

Precision Joining for Structural, Sheet Metal, and High-Finish Applications

SFC Tec Inc. offers a full suite of welding services to support both structural fabrication and high-precision assemblies. From traditional MIG/TIG welding to advanced laser welding, we ensure strong, clean, and consistent welds tailored to your project’s requirements.

Standard Welding Capabilities

We provide a range of industry-standard welding processes for aluminum, stainless steel, and mild steel:

- GMAW (MIG Welding) – Efficient and strong welds ideal for structural components, brackets, frames, and general fabrication.

- GTAW (TIG Welding) – High-precision, clean welds suited for stainless steel, aluminum, thin materials, and cosmetic requirements.

- FCAW (Flux-Cored Welding) – Excellent for thicker steel sections, outdoor welding, and high-strength applications (offered as needed).

These processes support everything from heavy fabrication to fine detail work.

Where Welding Fits Into Your Project

We commonly weld:

- Custom sheet metal enclosures and cabinets

- Brackets, frames, and structural assemblies

- Aluminum and stainless precision assemblies

- Prototyped or production sheet metal designs

- Components that require both cutting/bending and welding steps

Our combination of traditional welding expertise + modern laser welding capabilities ensures we can meet both high-strength and high-precision requirements.

Laser Welding — Advanced New Welding Technology

For applications requiring exceptional precision, minimal heat distortion, and premium aesthetics, we offer modern laser welding services.

Benefits include:

- Extremely clean, narrow weld seam

- Low heat input → reduced warping

- Minimal post-processing or finishing

- Highly consistent weld quality

- Ideal for aluminum and stainless sheet metal, enclosures, and precision assemblies

Laser welding is perfect for projects where tight tolerances, appearance, or minimal distortion matter.

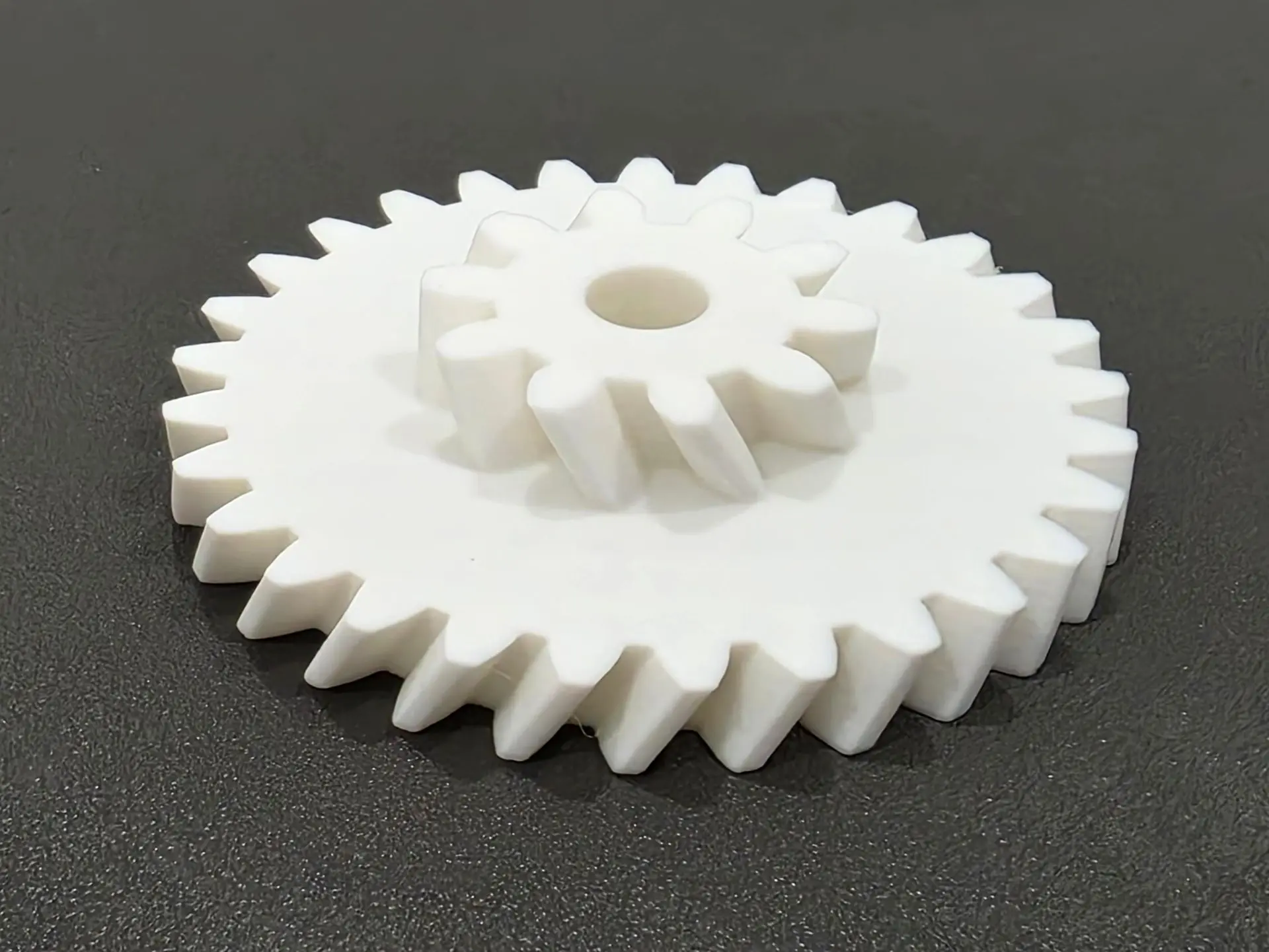

3D Printing & Prototyping

To help you refine designs and reduce risk before committing to full-scale machining or fabrication, we offer 3D printing as a flexible prototyping option.

Use 3D printing to:

- Test fit and function

- Validate concepts and ergonomics

- Review design changes before cutting metal

- FDM and SLA 3D Printing technologies

Whether as a standalone service or integrated with our CNC machining and fabrication workflows, 3D printing can save both time and cost in early development stages.

3D Design, CAD Modeling & DFM Support

We use SolidWorks and Autodesk Fusion 360 for custom product design, modeling, and manufacturing preparation.

Our design and engineering support includes:

- 3D CAD modeling

- Detailed manufacturing drawings

- Design for Manufacturing (DFM) reviews

- CAM programming for CNC machining

- Design refinement for bending, welding, and cutting

By resolving details in the digital stage, we ensure a smooth transition from design to manufacturing and help avoid costly rework later.

Metal Products & Local Material Supply

For our customers in Central Utah, SFC Tec Inc. also supplies select metal products and raw materials.

Through our network of trusted suppliers, we can provide:

- Sheet metal

- Angle iron

- Tubing and pipe

- Bar stock and structural shapes

If you’re building a project and need materials sourced quickly and competitively, we can help you get the right materials on time and at a fair price.